Metal Injection Molding

Metal Injection Molding is a practical alternative to traditional production processes such as machining, press sintering and lost-wax casting.

Contact us for more information on our MIM process and custom MIM micro components.

Contact us for more information on our MIM process and custom MIM micro components.

Benefits of Metal Injection Molding

- Highest degree of design freedom for complex shapes and geometries

- Functional integration of various features, such as lateral drillings, interior and exterior threads and gear teeth

- Provides practical economic solutions to increasingly stringent material and product design requirements

- Excellent batch to batch repeatability with exceptional process capabilities

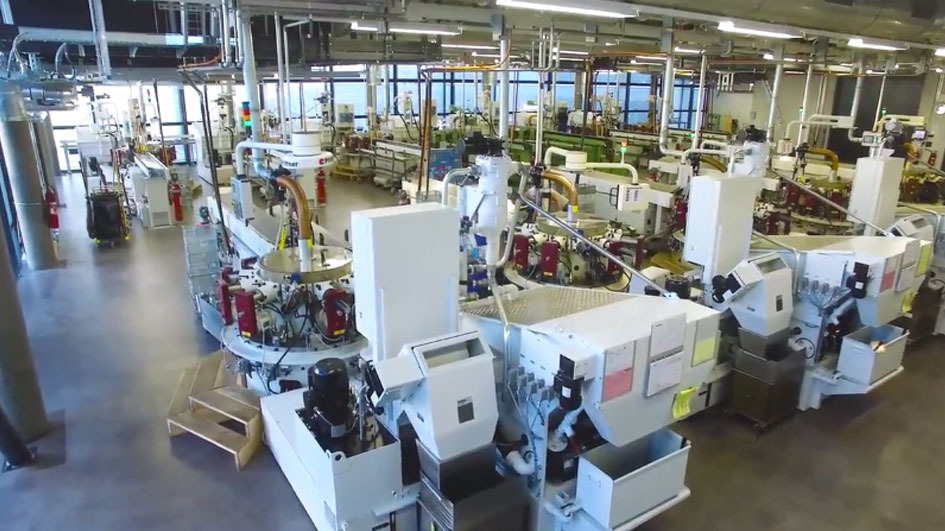

- Very high volume production series run on fully-automatic injection molding machines using multi-cavity tools

- Components can be heat and surface treated, plated, welded and soldered

Materials

- Low Alloy Steels

- Stainless Steels

- Titanium

- Heavy Alloy

See brochure for additional information on material properties.