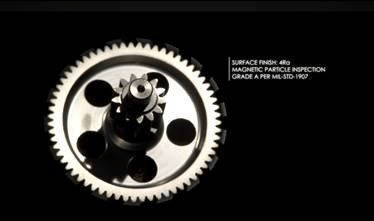

Precision Gears

China Equipment Partsdesigns, engineers, validates and optimizes custom solutions to meet the most challenging program requirements. Our high precision gears and custom gearbox solutions meet quality standards up to AGMA Q12 or AGMA 2015/ISO 5 specifications.

Diametral Pitch: 16 – 200 (1.5 – .125 Module)

Outside Diameter: 6mm (.24”) to 102mm (4”)

Pressure Angles: 14.5, 20, 22.5 or 30 degrees

Materials: Steels (alloy, stainless and carbon), bronze, brass, aluminum, Delrin®, nylon and other technical plastics

Secondary Operations: grinding, milling, honing, laser and EB welding, broaching and EDM processing

Surface Treatments*

- Heat treating: carburizing, induction and nitriding

- Passivation

- Magnetic particle inspection

- Nital etch

- Plating: chrome, nickel, Armoloy®, cadmium, anodize, black oxide, Melonite®, electroless nickel and precious metals

- Titanium nitride

- Electro polishing

- Tuftriding®

- Electrolyzing

*NADCAP certified vendors if required

65,000 ft2/6038 m2 manufacturing campus in Farmingdale, New York

ISO 9001, ISO 13485, AS9100, ITAR

Prototyping: China Equipment Partsmaintains a dedicated prototyping center with EDM capability that allows us to support our customers requiring quick turn proofs of concept

Gear Cutting: CNC and manual Gleason Pfauter, Fellows, Mikron & Barber Coleman machines for shaping and hobbing

Gleason Bevel Gear Cutting: Dedicated Gleason bevel gear cutting area

Grinding: Studer CNC and manual, Tschudin OD & ID grinders

Full complementary capability: CNC milling, large and small diameter CNC turning (multi-axis), lathe, mill and drill

Assembly: 4,500 ft2 of temperature controlled with electrical outlets and compressed air at every assembly position. Fully equipped for mechanical and electromechanical assembly and testing. ESD compliant and J-STD-001 certified

Clean room: 1,000 ft2 10K certified clean room

Gear Inspection and Metrology: PECO ND 300 Gear CMM, 2 Brown & Sharp CMM, Keyence vision systems, Vision System, OGP Optical comparators, over 60 gear testers, 150+ master gears

Passivation: Robotically controlled citric acid passivation